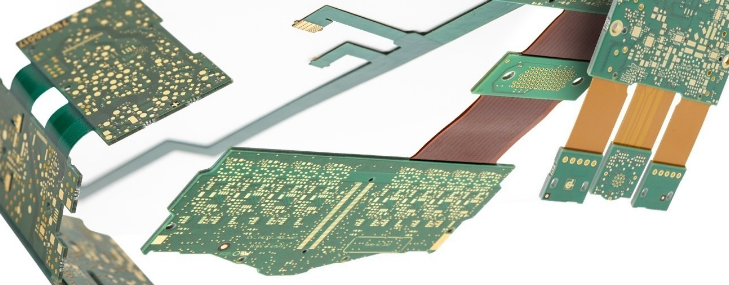

As the demand for miniaturized and durable electronics continues to surge, rigid flex PCB fabrication has become indispensable in industries such as medical devices, automotive systems, and aerospace applications. However, a critical question remains at the forefront of every engineer's mind: What is the actual cost of fabricating rigid flex PCBs in 2025?

This comprehensive guide will delve into the real cost structure, provide global price comparisons, and offer actionable tips to optimize your budget—all using real USD pricing data to empower more effective planning.

1. What Influences Rigid Flex PCB Fabrication Costs in 2025?

The cost of fabricating rigid flex PCBs is shaped by a multitude of technical and design elements. Below is a detailed breakdown of how each factor impacts your budget:

Layer Count: For an order of 100 units, a basic 4 - layer rigid flex PCB typically ranges from $38 to $50 per unit. In contrast, an 8 - layer version may command a price of $55 to $75 per unit. This price increase is attributed to the additional requirements for materials, lamination processes, and drilling operations.

Materials Employed: The use of polyimide cores, FR4 for rigid sections, and high - temperature adhesives significantly contributes to the overall cost. Opting for premium polyimide can elevate the cost by $3 to $7 per unit.

Surface Finish: ENIG, a commonly selected surface finish, adds approximately $0.80 to $1.20 per unit. On the other hand, hard gold finishes can drive up the price by $2 to $4 per unit.

Copper Weight: Compared to the standard 1 oz copper layers, 2 oz copper layers can cause the cost to increase by 10 - 20%.

Via Types: Microvias, particularly stacked microvias, can add $5 to $12 per unit to the cost, with the exact amount depending on the complexity of the design.

Tight Tolerances and Controlled Impedance: These features, which are crucial for high - speed circuits, may result in an additional cost of $3 to $6 per unit.

Typical Pricing Overview:

2. Global Pricing Comparison for Rigid Flex PCB Fabrication in 2025

Geographical location significantly influences the cost of rigid flex PCB fabrication when sourcing services:

While North American and European suppliers excel in quality, Asia (particularly China) remains the most cost-effective choice for both prototyping and large-scale production.

3. Volume-Based Price Breakdown for Rigid Flex PCB Fabrication

Unit costs decrease significantly with higher order volumes. Here’s a detailed breakdown:

Prototype (1–5 pieces)

Small Batch (10–100 pieces)

Mass Production (500+ pieces)

4. Rigid Flex PCB Fabrication Costs by Application Market

Industry-specific design and reliability requirements directly impact fabrication costs:

Consumer Electronics (e.g., smartwatches, foldable phones)

Medical Devices (e.g., wearable monitors, implants)

Automotive Systems (e.g., ADAS, dashboards)

Industrial & Military Electronics

5. Hidden Costs in Rigid Flex PCB Fabrication Projects

Final pricing includes more than just the PCB itself. Consider these additional expenses:

6. How to Cut Rigid Flex PCB Fabrication Costs Without Compromising Quality

Strategic design decisions can substantially reduce overall rigid flex PCB fabrication costs:

7. Why Choose I-tech electronics for Rigid Flex PCB Fabrication?

At I-tech electronics, we assist clients in optimizing costs while upholding reliability:

Our international clients in Europe and North America value our transparent pricing and engineering support. Whether you’re developing prototypes or scaling production, we deliver a seamless, cost-efficient process.

8. Conclusion: Understanding the True Costs of Rigid Flex PCB Fabrication

Rigid flex PCB fabrication costs fluctuate significantly based on layer count, regional sourcing, application requirements, and design complexity. In 2025, the average unit price spans from $20 to $90, with Asian suppliers like I-tech electronics delivering the optimal balance of quality and cost-efficiency.

Ready to get your precise cost estimate? Upload your Gerber files to I-tech electronics for a free, no-obligation quote within 24 hours—complete with detailed engineering feedback.