In the ever-evolving landscape of modern electronics, multilayer printed circuit boards (PCBs) have emerged as the linchpin, facilitating sleek and compact designs, seamless high-speed data transfer, and enhanced functionality across a diverse spectrum of devices. Whether it's the smartphones we carry daily, the servers powering the digital world, automotive engine control units (ECUs), or sophisticated satellite systems, multilayer PCBs are integral to their operation. However, as the sophistication and intricacy of these boards increase, so do the associated costs. The question on everyone's mind in 2025 is: what is the actual price tag of multilayer PCBs? This comprehensive guide delves deep into pricing structures, uncovers hidden costs, compares suppliers, and presents savvy strategies to optimize and reduce your overall expenditure.

In the ever-evolving landscape of modern electronics, multilayer printed circuit boards (PCBs) have emerged as the linchpin, facilitating sleek and compact designs, seamless high-speed data transfer, and enhanced functionality across a diverse spectrum of devices. Whether it's the smartphones we carry daily, the servers powering the digital world, automotive engine control units (ECUs), or sophisticated satellite systems, multilayer PCBs are integral to their operation. However, as the sophistication and intricacy of these boards increase, so do the associated costs. The question on everyone's mind in 2025 is: what is the actual price tag of multilayer PCBs? This comprehensive guide delves deep into pricing structures, uncovers hidden costs, compares suppliers, and presents savvy strategies to optimize and reduce your overall expenditure.

1. Why Pricing Multilayer PCBs Matters

In the competitive electronics market, precise knowledge of multilayer PCB costs is crucial. It helps with accurate planning, design optimization, and better negotiations with manufacturers, whether for prototyping or mass production.

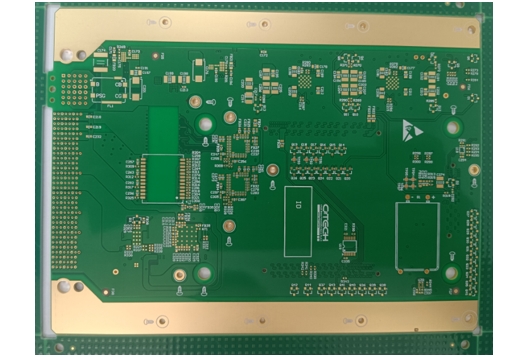

2. What Is a Multilayer PCB?

A multilayer PCB has over two copper layers, separated by insulation and connected via vias. Common types include 4 - layer (for basic microcontrollers), 6 - layer (mixed - signal designs), 8 - layer (high - speed networking), and 10+ layers (military, medical, etc.). Materials range from standard FR4 to advanced ones, with cost differences up to $1.50 per cm².

3. Key Factors That Affect Multilayer PCB Prices

4. Price Breakdown by Layer Count

Layer Count | Estimated Cost (per cm²) | Notes |

4-layer | $0.80–$1.20 | consumer-grade applications |

6-layer | $1.00–$1.60 | for signal integrity, EMI control |

8-layer | $1.50–$2.50 | Complex routing, high-speed signals |

10-layer | $2.80–$4.00 | Dense systems, CPUs, DDR memory |

12+ layers | $4.00–$7.00+ | Telecom, aerospace, medical systems |

All estimates based on FR4, 1oz copper, ENIG finish, and MOQ of 50–100 units.

5. Hidden Costs to Watch Out For

When budgeting for multilayer PCBs, it's essential to account for additional charges that manufacturers may impose on top of the base price:

Engineering Setup Charges

This covers expenses for tooling, CAM review, and design for manufacturability (DFM) checks. You can expect to pay $50–$150 for each new design, a one-time cost that can significantly impact small-batch projects.

Impedance Control

Required for complex designs with differential pairs or matched-line configurations, impedance control adds 10–25% to the PCB cost. For example, a board initially priced at $1.50 per cm² could end up costing around $1.80–$1.90 per cm².

Electrical Testing

Manufacturers offer flying probe or fixture testing to ensure electrical integrity. Costs range from $0.01–$0.05 per electrical net, or a flat fee of $20–$60 per testing job.

Certification Costs

Compliance with standards like UL, ISO13485, or IPC Class 3 comes with a price tag. Depending on the documentation requirements, expect to pay an extra $30–$100 per batch.

Packaging and Shipping

Specialized packaging, such as vacuum-sealed bags, can cost $5–$10 per batch. Air shipping via carriers like DHL or UPS typically ranges from $30–$80, depending on the destination and weight of the shipment.

Reorder Fee

If you need to modify design files or reconfigure the production setup, a reorder fee of $20–$40 may be applied, so it’s crucial to finalize designs before production.

6. Cost Comparison: China vs. USA vs. Europe

Region | Avg. 6-Layer PCB Price (100x100mm) | Lead Time | Notes |

China | $11–$15 per board | 5–10 days | Best for affordability, even with shipping |

USA | $25–$40 per board | 7–14 days | Ideal for high-IP or regulated industries |

Europe | $28–$45 per board | 10–20 days | Strong support for automotive/medical PCBs |

Chinese suppliers dominate the mid- to high-volume market with aggressive pricing and quick prototyping capabilities, especially for 4–10 layer PCBs.

7. How to Get an Accurate Quotation

To ensure you receive precise and fair pricing, rather than ambiguous or inflated estimates, it's crucial to submit the following essential files and details:

For instance, I-tech offers convenient instant quoting tools. These tools leverage the submitted parameters to calculate live pricing, providing you with quick and accurate cost estimates

8. Cost-Saving Tips for Multilayer PCB Orders

Making astute design and procurement choices can slash your overall costs by up to 40%. Here are some effective strategies:

Use Standard Materials

For the majority of designs, FR4 (TG150) proves to be more than adequate. Reserve specialty laminates for applications with specific requirements. This approach can yield savings of $0.30–$0.80 per square centimeter.

Optimize Stack-Up Design

Streamline your PCB layout by minimizing unnecessary layers. Employ intelligent routing techniques and make efficient use of ground planes. For example, reducing the layer count from 8 to 6 can lead to savings of $0.60–$1.00 per square centimeter.

Avoid Over-Specification

If gold contacts aren't essential, opt for HASL over ENIG. Similarly, refrain from using blind or buried vias unless space limitations demand them. Depending on the design, these adjustments can lead to savings of 10–35%.

Combine Orders / Panelize

Grouping multiple PCB designs onto a single panel helps distribute tooling and setup costs. This strategy is particularly beneficial for orders exceeding 100 pieces. Panelization can reduce the per-board cost by 15–25%.

Flexible Lead Times

Reserve rush services for truly time-sensitive projects. Choosing standard lead times can save an average of $3–$8 per board. Leveraging I-tech’s manufacturing timelines, you can plan ahead and lock in more favorable pricing.